Circular Elegance, Certified: How Cradle to Cradle Elevates Sustainable Luxury

From Linear to Circular Craft: The Principles Behind Cradle to Cradle

Material Health Without Compromise

Designing for Perpetual Use

Clean Energy and Responsible Water

Levels That Signal Progress: Bronze to Platinum

Case Studies in Quiet Brilliance

Plant-Based Textiles With Palatial Softness

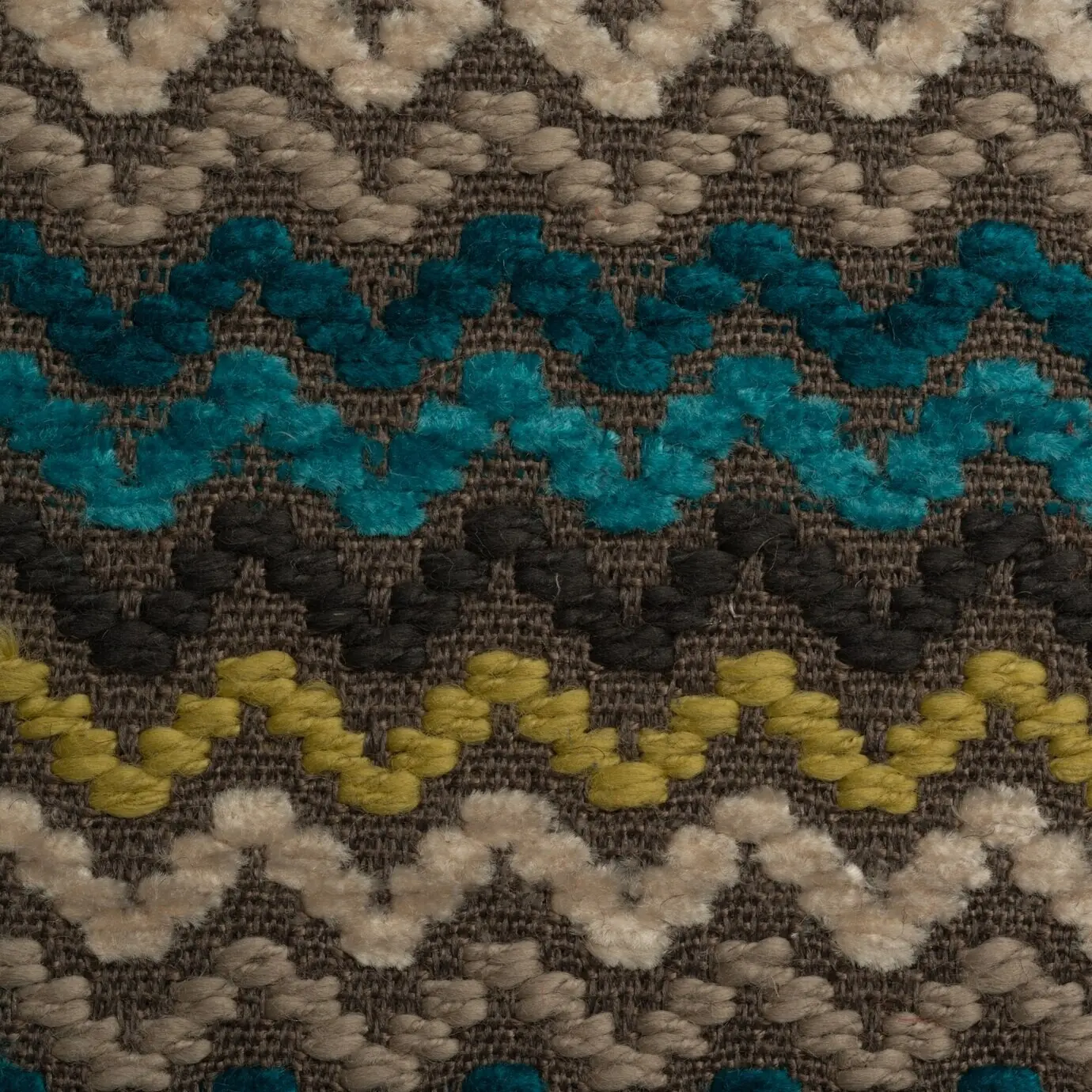

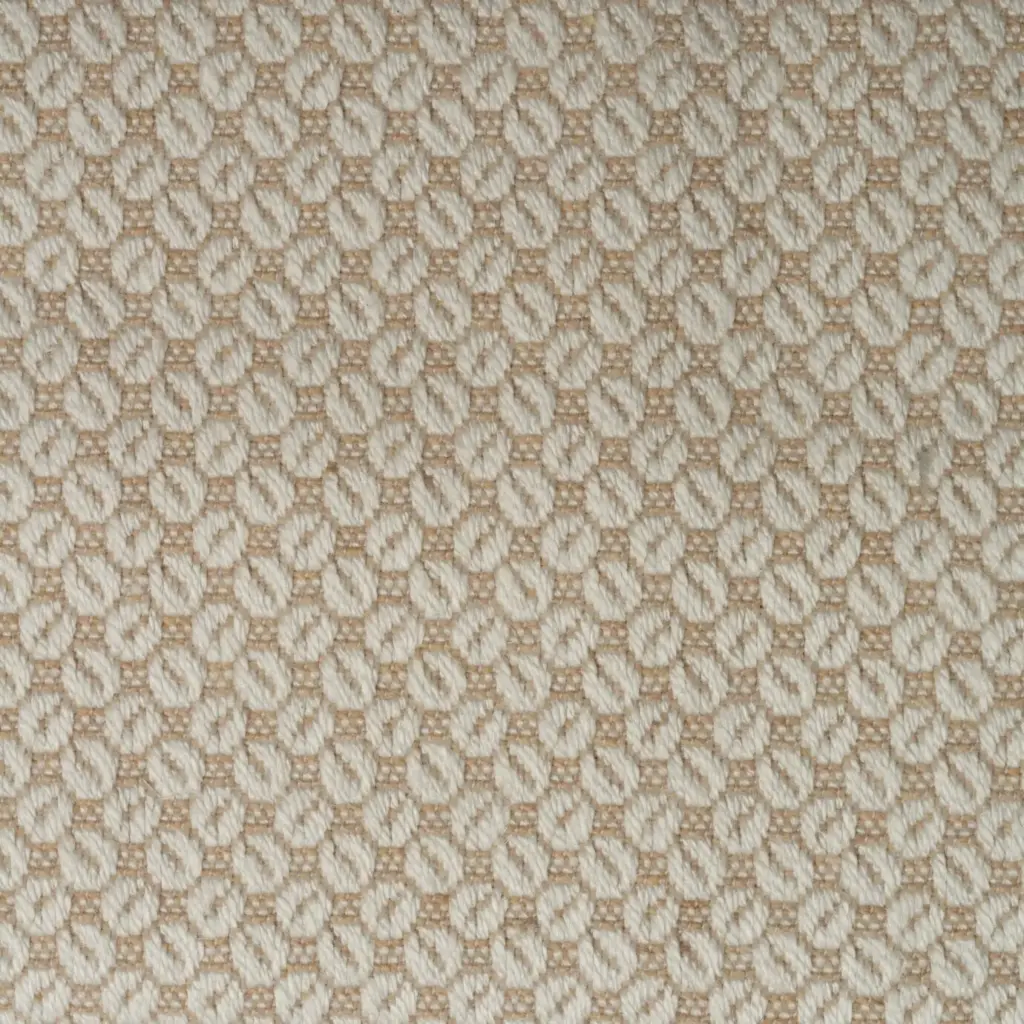

Imagine a bio-based textile woven from traceable cellulosic fibers, finished with optimized auxiliaries that preserve drape and sheen. The mill uses renewable electricity and carefully treats process water, while designers select a single compatible polymer for trims. When wear finally appears, panels detach for repair or replacement. Post-use, fibers enter a biological cycle or a recycling stream, depending on blends. The result feels luxurious to the touch and reassuring to the mind—comfort without compromise, craftsmanship that anticipates care, and chemistry that welcomes proximity.

Reclaimed Precious Metals, Radiant Again

A jeweler partners with a responsible refiner reclaiming gold from post-consumer sources, minimizing mining pressures without sacrificing brilliance. Each batch holds digital documentation of origin, refining practices, and energy profile. Alloys are tuned to avoid problematic constituents, making future re-refining straightforward. Settings use modular designs to release stones cleanly, extending both materials’ lives. Clients receive lifetime resizing and polishing services, transforming ownership into stewardship. The piece glows not only with luster but with narrative continuity—history refined, chemistry improved, and value renewed indefinitely.

Modular Interiors That Travel With You

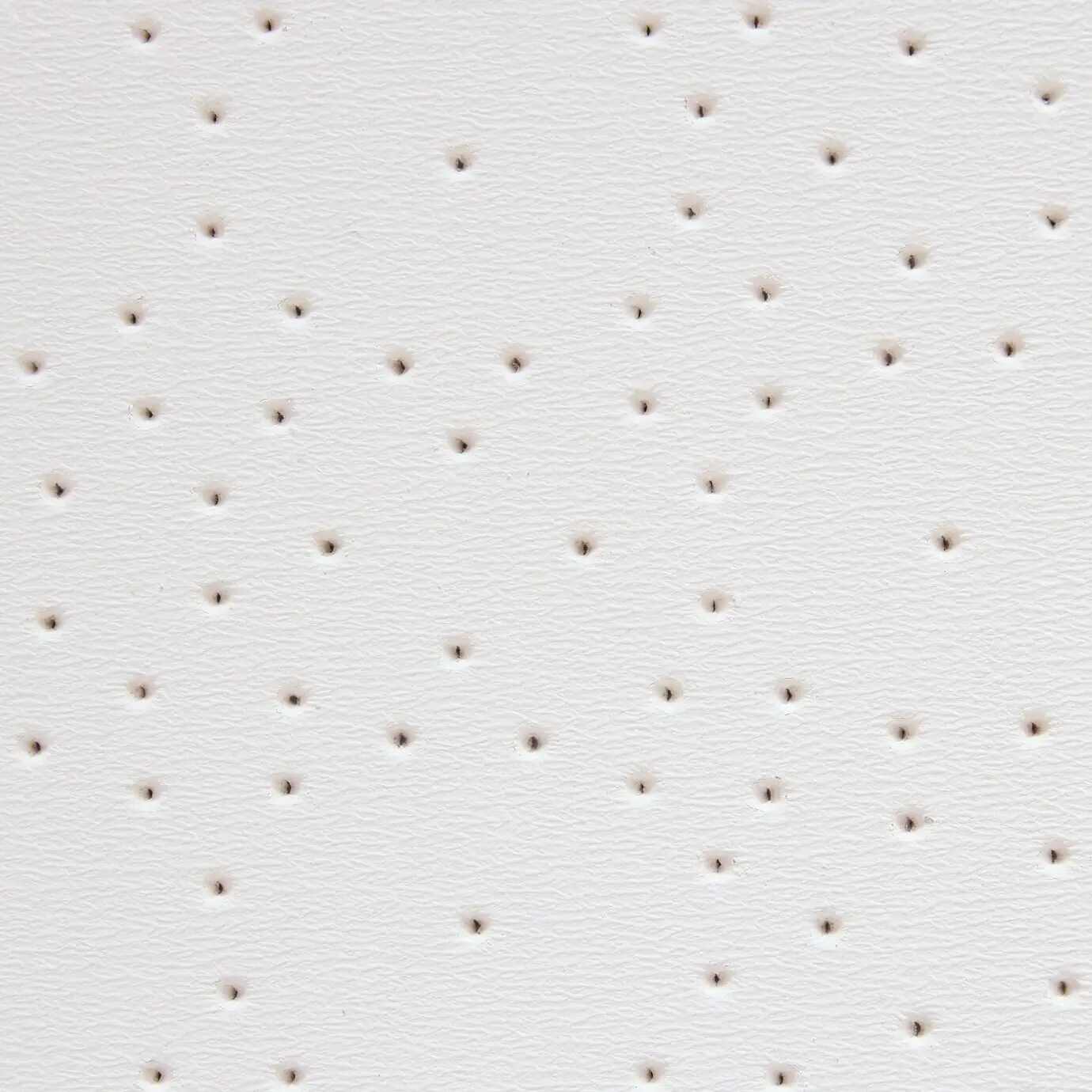

A hospitality group specifies modular carpets and wall panels engineered for disassembly, each component mapped for refurbishment or material recapture. Connectors are standardized and visible, enabling quick swaps between suites or yachts without damage. Manufacturers run on renewable power and maintain tight wastewater controls to protect nearby waterways. When patterns change, inventory returns for fiber-to-fiber recycling or component resale. Guests notice quiet comfort and enduring quality; operators appreciate reduced downtime and waste. Circularity becomes a service experience—soft underfoot, precise in execution, and remarkably resilient.

Comparing Credentials With Care

When FSC Complements Circular Design

For cabinetry, veneers, packaging, or cellulose-based fabrics, FSC ensures responsible sourcing and traceable custody. Pairing FSC with Cradle to Cradle strengthens both origin integrity and end-of-life strategy: responsible forests on the way in, circular flows on the way out. Designers can specify mono-material fiberboards, avoid mixed laminates, and choose reversible adhesives. The result is wood that feels honest, ages handsomely, and returns to cycles as clean feedstock, linking forest health to workshop excellence and a product’s graceful second and third chapters.

Declare Labels for Radical Transparency

Declare shines when ingredient clarity is paramount, helping teams reveal contents, identify hazards, and signal Red List compliance. In luxury interiors or fixtures, a Declare label can ease architectural approvals and satisfy clients hungry for details. Combine that clarity with Cradle to Cradle optimization and you gain both disclosure and direction—showing what’s inside while proving performance improvements. Transparency becomes reassurance rather than risk, inviting dialogue with specifiers, artisans, and end-users who value candor as much as craftsmanship, and expect verification beyond aesthetic persuasion.

Harmonizing Frameworks Without Redundancy

Teams succeed when they map overlaps and plan data once for many uses. Ingredient inventories can feed both material health assessments and Declare disclosures; chain-of-custody work can serve FSC and downstream accountability. A single bill-of-materials, robust supplier questionnaires, and shared lab reports save time and cost. With a unified evidence library, certification timelines shorten and storytelling strengthens, avoiding contradictory claims. The objective is elegant governance: one truth, many audiences—clear to auditors, inspiring to clients, and genuinely useful to designers making better choices daily.

The Path to Certification: Practical Roadmap

Value Beyond Compliance: Why It Matters

All Rights Reserved.